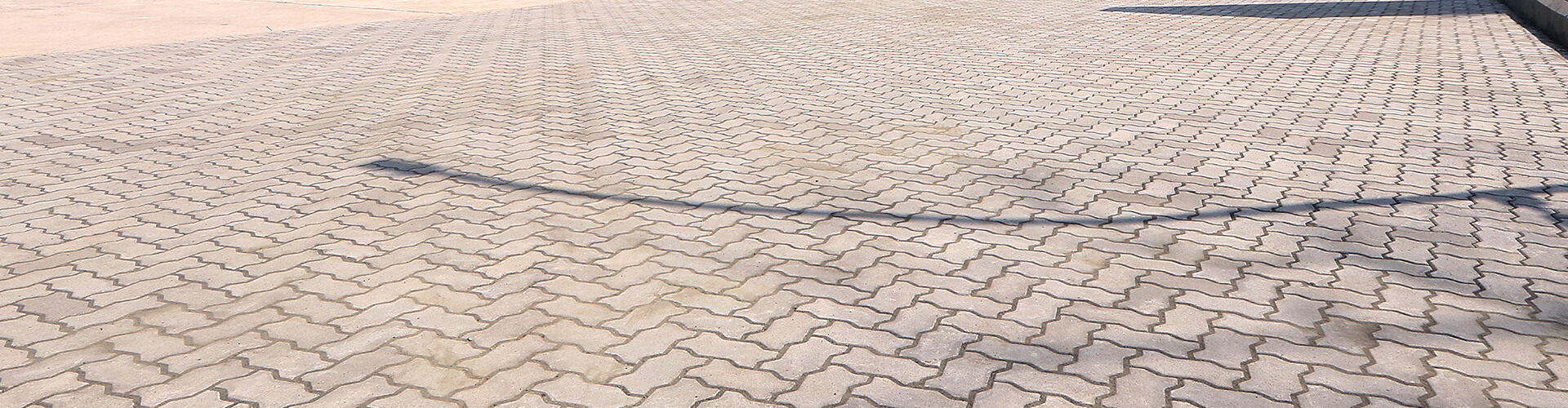

Concrete Interlocking Paver Installation

The following guideline is an overview of the proper steps involved when installing interlocking concrete pavers where no special circumstances are present. Your specific project will be unique and may require additional steps.

Things to Keep in Mind

- Proper base material should always be used even if you feel that your underlying sub-grade is suitable.

- Remember to adjust grade for proper drainage.

- Remember that once sand bedding is installed and leveled, to not disturb prior to laying of pavers.

-

Step 1: Preparing the Base

It is important to provide a well compacted, stable base on which to begin the paver installation. In some cases, this will require extensive excavation of unsuitable sub-grade material.

Excavate the Site:Excavate all unsuitable, unstable, or unconsolidated sub-grade material. When estimating the depth of excavation, consider the final grade of the project. Add the height of the paver unit, the depth of bedding sand, and the thickness of the compacted base material to get an estimate of needed depth.

Fill and Compact the Base:Thickness of Compacted Base:

- Pedestrian Traffic: 3"–4"

- Vehicular Traffic: 4"–5"

- Large Vehicular Traffic -8"

Fill the excavated site with the appropriate amount of paver base material (Class II Road Base is recommended), and compact using a vibrating plate compactor. The base must be well compacted and level to provide a smooth, even surface on which to lay the bedding sand.

NOTE: When preparing the grade of the base, be sure to provide a 1/8"–1/4" of drop per foot for proper drainage.

Step 2: Bedding Sand

The pavers will be set in a bed of sand. It is this sand bedding that will provide final leveling properties as well as help secure the paver units in place.

Install 1" of Bedding SandClean, sharp concrete sand, 1" deep, should be used for the sand bedding to level the sand by screed level.

IMPORTANT: Do NOT walk on or disturb screeded sand bed

Step 3: Edge Restraint

A stable edge restraint is necessary to eliminate any lateral movement of your pavers and sand bedding. Edge restraints can be either and existing hard edge or KERB STONE

Installing the Edge Restraint:

If an existing hard edge restraint (such as the side of a house) does not exist, you will need to either install a pre-manufactured KERB STONE manufactured by AASHAPURA PAVERS

Step 4: Laying the Pavers

It is now time to begin laying the pavers onto the bedding sand and fitting them into the desired area of your paver project.

Field and Border Stones:

When laying the pavers onto the bedding sand, you want to work in a forward motion. Start the process in either a 90° corner or within the field by using a pre set string to guide straightness of pavers. Do NOT step on the bedding sand.

Place pavers flat on the sand bed. Do not tilt the pavers into place as this will disturb the level of the bedding sand. When a row or pattern is in place, use them as a guide for subsequent pavers. The spacing between the pavers should be hand tight (pavers have built-in spacers on their edges to provide a 1/8" joint).

PRO TIP: When laying pavers, check every few feet with a string line to maintain a straight line.

Trimming May Be Required:As the field moves closer to the edge restraint or concrete border, cutting may be required to fit the pavers to the desired space. Cutting of pavers should be done with a diamond masonry blade and saw or if needed, it can be accomplished using a block splitter, but a splitter will not allow the precision cut provided by a masonry saw.

Step 5: Vibrate the Pavers

Once the entire paver field and borders have been placed, you will need to run a vibrating plate compactor over the paver project to being the interlocking process.

Initial Setting and Lock-up:

Rent a vibrating plate compactor from your local equipment rental company. Once the pavers and border have been placed, spread a light layer of sand over the pavers and make a single pass using this plate compactor.

This single pass will help set the pavers into the bedding sand, and cause some sand to move up between the joints of the pavers. This is the initial stage of the "interlock".

Step 6: Sanding the Pavers

The second step of the interlocking process involves working sand down between the paver joints to achieve final "lock-up".

Final Compaction and Lock-up:

Spread dry paver joint sand or masonry sand over the surface of the paver area approximately 1/4" deep. Using the vibrating plate compactor, pass over the sanded pavers to allow sand to properly fill the voids between the pavers.

You will generally need to run the plate compactor over the pavers 2 or 3 times, or until the pavers no longer settle into the sand bedding. This process will achieve final lock-up and completely fill the voids between the pavers.

Sweep remaining sand into voids until they are completely filled. A light pass with a weed blower will help rid the surface of excess sand and dust. Be careful to insure the joint sand remains in the voids.